So You Need Heat—But What Kind?

Alright, let’s face it—buying a new electric process heater isn’t the flashiest business decision you’ll ever make. There’s no ribbon-cutting, and probably no one’s Instagramming about it. But if you choose wrong? Things get expensive, or even dangerous, real quick. Getting the right fit makes a world of difference in your workflow, safety, and bottom line.

Getting Real About Your Heating Needs

Start with the basics: what are you actually trying to heat? Some people need to keep water or oil at a steady temp, others are blasting air through ductwork, and a few might be dealing with gnarlier stuff like chemicals or steam. Take a minute to jot down what you’re heating, how much of it you’re working with, and the temperature you need to reach. (Quick tip: Don’t trust your gut—grab real measurements. Wishful thinking rarely ends well here.)

Next, ask how precise the temperature needs to be. Are you working with an industrial bakery that will freak out if temps swing a degree, or is it just about not freezing your pipes? This is where knowing your own process pays off.

Space: The Final Frontier (For Equipment)

All process heaters are not created equal, and some come in shapes and sizes you wouldn’t believe. Look around—do you have room for a giant unit? Or are you hoping for something compact to hide in a closet or mechanical room? Nothing’s worse than buying brand-new equipment only to realize it doesn’t actually fit through the door.

Energy & Budget—Keeping It Real

Your power setup matters. Can your facility handle bigger voltage, or are you limited by the grid? Getting an electrician to check your panel and wiring ahead of time will save a ton of grief later. Think about long-term energy bills, too. Sometimes, spending a bit more upfront on an efficient heater pays back every month when your utility statements make you smile (or at least cringe less).

Maintenance and Reliability

Who’s going to look after this thing? Is your team hands-on, ready to check on heaters every day, or is it more of a “call for help when it breaks” vibe? Go for models with features that fit your reality. Some heaters are basically maintenance-free, while others need regular TLC.

The Different Types—A Quick Rundown

- Immersion Heaters: Direct-contact pros, perfect for tanks or reservoirs of liquid. Think big soup pots, but for chemicals or oil.

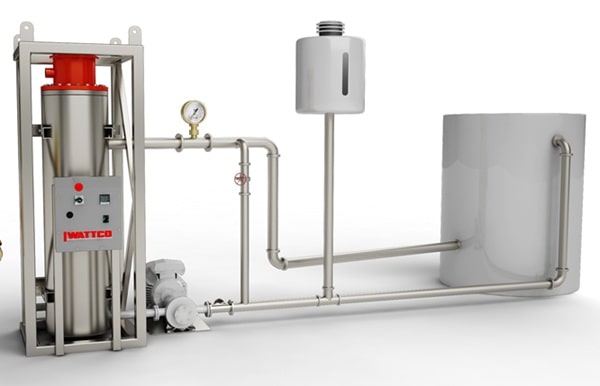

- Circulation Heaters: The MVP for fluids that need to be hot and moving, like oil lines or de-icing systems.

- Duct Heaters: If you’re blowing hot air into a space or through a process, these are your go-to.

- Cartridge & Strip Heaters: Small but mighty, great for localized spots or equipment that needs a little help.

Don’t Go It Alone

Honestly, don’t be afraid to ask for help. Equipment suppliers and reps have seen it all, and they’re used to questions (everyone asks them, trust me). Bring your numbers, your space details, and any “must-have” features when you chat.

Heating your process right means fewer headaches, better results, and more time actually running your business. Make your choice, get it installed, and get back to what you do best. And hey, you might actually get to forget about your heater—for all the right reasons.