What Are Casters and Wheels?

Casters and wheels are essential components that effortlessly move equipment, carts, and entire workstations across various floor surfaces. Their versatility is why they are found in virtually every industrial setting, from warehouses and manufacturing plants to hospitals and laboratories. By transforming stationary loads into movable ones, casters and wheels unlock productivity, adaptability, and efficiency for modern workplaces.

The key to unlocking these benefits lies in selecting quality casters suited for your specific environment and operational needs. Trusted brands like Blickle Casters provide various solutions engineered to meet industry standards for durability, ergonomic movement, and safety. Their product lines are recognized for consistent performance and robust construction, making them a preferred choice for industries aiming to minimize downtime and maintain smooth operations.

Why Casters Matter for Productivity

Productivity in industrial settings depends on moving heavy loads quickly, safely, and with minimal physical strain. OSHA data shows that poorly designed or worn-out equipment, like wrong casters, can cause accidents, damage, and injuries, leading to lost workdays and medical costs. Properly matched casters lower effort, reduce strain, and prevent injuries. With the right casters, workers save time and focus on core tasks, boosting throughput and reducing bottlenecks. High-quality casters are an investment in workforce capacity and efficiency.

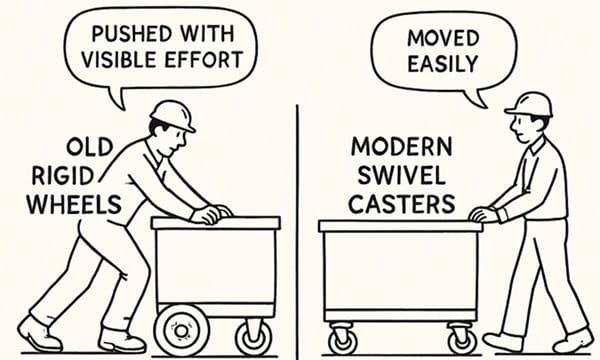

Types of Casters for Every Need

Industrial casters are versatile and can be customized to meet specific operational needs. They come in rigid, swivel, locking, and specialty types. Rigid casters are ideal for straight-line movement, while swivel casters offer 360-degree mobility. Locking casters secure equipment, while specialty casters are designed for specific environments like chemical-resistant labs or heat-resistant bakeries. Making informed choices about caster type and wheel material can lead to long-term savings by preventing floor damage and optimizing workflow.

Safety Considerations in Caster Selection

Safety isn’t just about equipment functioning as intended but also about proactively preventing injuries and damage. Using slip-resistant wheels, reliable brakes, and adhering to correct load ratings are non-negotiable aspects of industrial safety. Failure to perform routine inspections and respect load capacities is among the top causes of workplace injuries involving carts and dollies.

Choosing consistent quality like that established brands offer means you can rely on critical features: precision bearings, reinforced forks, and wheels designed to grip rather than slip. Each consideration helps lower the risk of tip-overs, pinched fingers, and costly workplace accidents, directly supporting your company’s safety culture.

Maintenance Tips for Longer-Lasting Casters

Routine maintenance is crucial for preventing unexpected breakdowns and extending the lifespan of casters. Simple practices include inspecting wheels for debris, applying lubrication to moving parts, and replacing worn components promptly. Regular inspections, removing built-up grime, and lubrication are essential. Damaged or uneven wheels and bearings should be replaced immediately to prevent additional wear. Staff should be educated on the signs of impending failure. Supported by facilities management best practices, proactive upkeep reduces downtime and prolongs equipment and casters’ operational readiness.

Emerging Technologies in Casters and Wheels

The world of casters and wheels is rapidly evolving with technological innovations like self-cleaning coatings that repel debris and reduce cleaning needs. Advances in materials have led to quieter, smoother wheels from vibration-dampening polymers, and some now feature sensors and IoT for real-time status updates. These smart solutions improve maintenance and asset tracking by lowering labor, reducing manual inspections, and supporting data-driven safety. Industries adopting these set new standards for efficiency, safety, and lifecycle management across the supply chain.

Conclusion: Optimizing Operations with the Right Casters and Wheels

Casters and wheels are vital for efficiency, safety, and flexibility in industrial environments. Choosing the right type, material, and load rating ensures smooth movement, protects floors, and reduces worker strain. Regular maintenance and emerging tech like smart sensors extend lifespan and reliability. Investing in quality casters boosts productivity, reduces downtime, and creates safer, more efficient workplaces—making them essential for success.